Timber-Frame 4x10 Outbuilding Blueprints - How to Get the Perfect Shed Building Plans

Look at the entrances to your yard. Spread a layer of fist or baseball sized stone followed by a layer slightly smaller than a ping-pong ball. Once rim braces are up, other studs are placed perpendicularly between them and nailed to rim joists, as well as toe-nailed to the exterior walls. Beefing-up attic floor trusses to add an upper floor is simpler than fixing ground-floor studs because you could reinforce joist system from above. If you have a greater slope, you may have to create a retaining (https://shedconstructionplans.com/gambrel-roof-barn-shed-plans-blueprints-20x24) wall and add fill to get a level site. Just construct sure that plastic doesn't contract the top of concrete.

We used a refrigerator door from dump. Frame and install the front and rear walls, leaving the top plates off at this time. This step by step woodworking project is about free lean to shed blueprints. Convert depth of gravel required to feet and multiply it by the square footage. As for indoor use inside outbuilding there wasn't that much space. It is now just a matter of cutting to length, gluing and screwing intermediate 75mm x 25mm battens to door slats covering all of the joins. Edge on sides and front with a metal drip profile. Note that the corners have two different widths so that when one overlaps the other and the whole corner is painted, the corners on all the walls looks equal.

You'll need enough to cover the full area covered by the gravel pad. Pour the concrete base and set the anchor bolts. The (additional resources) structure sits on skids, thus making the shed relocatable. But hey, your bins are probably a different size to mine anyway. If you don't need a larger construction in your garden, we recommend you to consider building this small scaled version, as it will be a durable constructions and it will keep the generator dry even during wintertime. Take your time to make sure everything is done properly, is level, and ensure air bubbles won't be an issue.

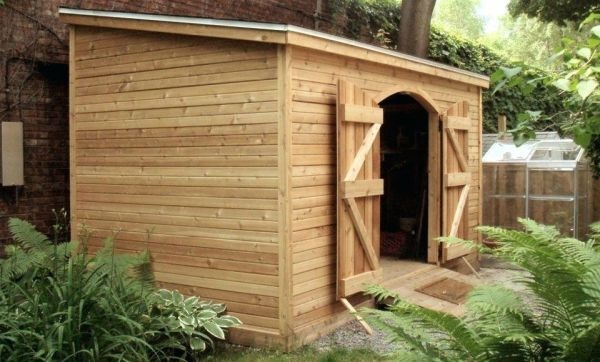

Shim the top of column tight to beam with lumber shims. Sturdy metal hardware takes place of traditional, time-consuming timber-frame joinery in this contemporary take on the classic storage shed. At the top plate, toenail through bird's-mouth into top plate to hold rafters temporarily. Set the 4 corner stakes, ensuring the corners are square. Use a spirit level to make sure trusses are plumb. Most people underestimate how much room their belongings would actually take up. Using a jigsaw, segment the roof into three parts at these two marks. The size of a outbuilding door could vary extensively, therefore you have to decide this aspect from very beginning.

You can easily build the outbuilding wider, if you want to store a larger quantity of firewood. Traditional homes often have sections of flat roof-over shed dormers, above porches and garages, and on balconies. Key to doing this with minimal damage to flooring and trestles is to cut only through subflooring and not into joists, which you need to provide stable support for your new fixtures. Roof trusses are manufactured so they are ready to install. Cut a patch with a crosshatch cutout for the vent or obstruction and place it over the top so that it overlaps on top of surrounding paper, and fasten with staples.

Install two 4-inch door hinges to top edge of each of three lids. Some jurisdictions and insurance companies also require sheds to be anchored. Wall with window plans Building side wall with window is a complex job, provided you use right drafts. You could also build a double wall around a home theater for exceptional soundproofing. The dimension of the ceiling joist depends on the span and what you plan to store in attic. Center the assembly on desired stud. Sistering does not reduce headroom - a consideration for basements or crawlspaces with low ceilings. Basically anything that could hang from a screw, you could hang in this stuff.

Work slowly to ensure that air doesn't get trapped as you add concrete. Mark that spot and continue on to next joist and joist after that. Joists are spliced over beams or other supports. This method proved easy enough in practice. The timber itself had nothing really wrong with it, it just hadn't been completely dried before being sold. The windows are shop built using plastic utility window sash that we found at a local home center. Use plenty of these in case a mighty wind comes. Ask your building inspector what's required in your area.